- Top

- Sustainability

- Seven & i Group Material Issues

- Material Issues 3

- Measures against Food Loss / Waste and Measures for Organic Waste Recycling

- Sustainability

- Statement

- Message from the Representative Director & Executive Chair (Kaicho)

- Basic Policies of Sustainability Initiatives

- Sustainability Management

- Stakeholder Engagement

- Business Partners

- Seven & i Group Material Issues

- Compliance

- Information Security and Personal Information Protection

- Human Rights Initiatives

- Human Capital Initiatives

- Responses to Climate Change (TCFD) and Nature (TNFD)

- Response Based on the Taskforce on Climate-related Financial Disclosures (TCFD)

- Taskforce on Nature-related Financial Disclosures (TNFD)

- Social Contribution Activities

- Disaster Reconstruction Support

- Disaster Assistance

- Overseas Initiatives

- Sustainability Data Book

- External Recognition and Awards

- SASB/GRI Index

- Index for Researchers

- Keyword search

- Editorial Policy

- Social

- Environment

Measures against Food Loss / Waste and Measures for Organic Waste Recycling

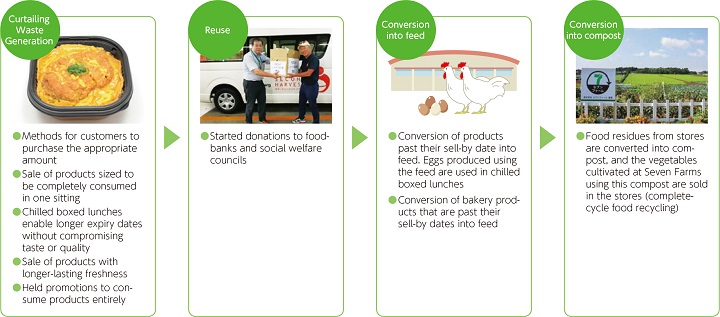

Food accounts for about 60% of Seven & i Group’s sales, and the “GREEN CHALLENGE 2050” Environmental Declaration has established food loss and waste / organic waste recycling countermeasures as one of its themes and is promoting initiatives. The “GREEN CHALLENGE 2050” aims to raise the organic waste recycling rate to 70% by 2030 and 100% by 2050, and the amount of food loss and waste* will be reduced by 50% by 2030 and 75% by 2050 compared to 2013.

*Amount generated per one million yen in sales

* Covering five food-related operating companies: Seven-Eleven Japan, Ito-Yokado, York-Benimaru, SHELL GARDEN, and Seven & i Food Systems

Our Approach to Reducing Food Waste

Initiatives to mitigate actual food waste generation are vital to addressing the societal challenge of reducing food waste. This theme is also positioned as the foremost priority in the fundamental principles of the Basic Act on Establishing a Sound Material-Cycle Society, and the Seven & i Group is also taking the initiative in mitigating the generation of waste as a foremost priority. We are additionally making efforts to ensure that we can recycle any food waste that is generated.

Amount of Food Waste Generation

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | ||

|---|---|---|---|---|---|---|

|

Amount generated per million yen of sales (kg)* |

22.35kg |

21.01kg |

20.28kg |

19.83kg |

17.68kg |

|

* Five food-related operating companies: Seven-Eleven Japan, Ito-Yokado, York-Benimaru, SHELL GARDEN, and Seven & i Food Systems

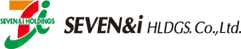

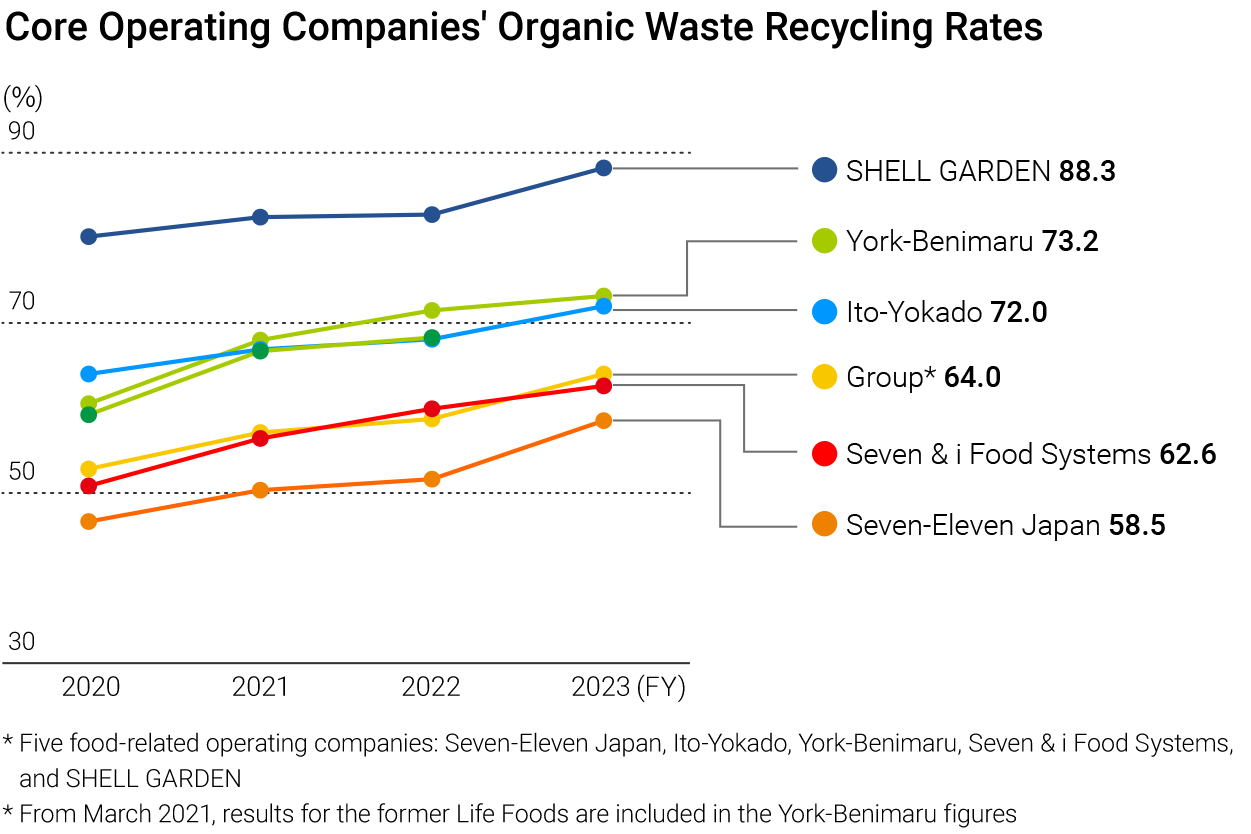

Initiatives Across the Entire Supply Chain

Seven & i Group continues to implement initiatives to reduce food loss / waste throughout the entirety of its supply chain. As one example, we are relaxing product delivery deadlines at Seven-Eleven Japan, Ito-Yokado, and York-Benimaru. Until now, our business practice was to use the “1/3 rule,” which entailed delivering products to stores before a third of the period between the date of manufacture and the expiration date had passed. Since 2012, as an initiative for reducing food loss, we have revised this to a “1/2 rule,” which relaxes delivery deadlines by allowing deliveries before half of the period between the date of manufacture and the expiration date has passed, for certain categories of products. In the fiscal year ended February 28, 2023, the target categories for this rule were expanded to include all non-refrigerated processed foods. In addition, for the Group's Seven Premium private brand products, we initiated the modification of expiration date labeling from the previous “date” to a “year and month” in the fiscal year ended February 29, 2020, and had rolled this out to encompass approximately 70% of all products by the fiscal year ended February 28, 2023.

Image showing relaxed delivery deadlines

Initiatives of Each Group Company to Reduce Food Waste

Each Seven & i Group company is implementing various innovations to reduce food waste in areas including sales methods and products.

For example, Seven-Eleven Japan is promoting the "Temaedori" initiative in collaboration with the Consumer Affairs Agency, the Ministry of Agriculture, Forestry and Fisheries, the Ministry of the Environment, the Japan Franchise Association, and the four major convenience store chains. The Temaedori Project is an initiative aimed at reducing food loss by encouraging customers purchasing food items that they plan to eat soon to choose from products placed in an immediately accessible location. This activity has also been expanded to Seven & i Group stores.

In addition, Seven & i Food Systems’ Denny's restaurants provide menus offering dishes with smaller servings that can be finished comfortably without leftovers. It also provides take-out containers, mottECO, for customers to take the leftovers home, when they wish.

In this way, Seven & i Group is also taking the initiative to reduce the generation of waste as a foremost priority, as well as stepping up recycling of food waste already generated. For example, York-Benimaru is converting fish ilium bones discarded by stores into feed. Moreover, 100% of waste oil, such as that generated from the frying oil used to cook delicatessen items at the stores of each Group company, is recycled.

Extending Expiration Dates of Original Daily Products

Seven-Eleven Japan has made technological innovations at the manufacturing factories. Reviewing the manufacturing processes and temperature / hygiene management has made it possible to ensure safety and security as well as improve taste and quality, such as by not using preservatives, along with extending expiration dates (developing products with longer-lasting freshness). Starting with chilled boxed lunches in 2009, Seven-Eleven Japan has extended the freshness of products such as gratin and doria, pasta dishes, sandwiches, and delicatessen items. As of the end of April 2024, about 85% of our original daily products have a sales deadline that is over 24 hours away.

Donations to Food Banks

Since 2017, Seven-Eleven Japan has been donating inventories to food banks* of processed foods left over as surplus when shops are closed or refurbished. As of the fiscal year ended February 28, 2019, it also entered into the “Agreement Pertaining to Social Welfare Activities through Product Donation” with local social welfare organizations and municipalities and launched similar initiatives. The donated products are distributed through social welfare organizations to organization and facilities that support people such as seniors, persons with disabilities, children, and the needy. As of the end of February 2024, it has concluded collaboration agreements with 44 partners.

In addition, Ito-Yokado has been donating pre-expired foods from some stores to food banks since the fiscal year ended February 28, 2018.

* Organizations engaged in the distribution, to those in need of support, of foods which, despite no quality concerns, could not be put to market or are surplus to households.

Donations to Food Banks (Ito-Yokado) (Cumulative Total)

| FY2021 | FY2022 | FY2023 |

|---|---|---|

|

Approx. 4,473kg |

Approx. 4,984kg |

Approx. 5,000kg |

Deployment of Eco Distribution

Seven-Eleven Japan has been promoting “Eco Distribution*” since 1994 as a system for appropriate processing and recycling of organic waste. As part of this system, we are endeavoring to recycle food products that have passed their sales deadlines into feed or compost.

* Eco Distribution: Seven-Eleven’s original waste recycling system

A recommended waste disposal provider for franchisees in each region collects all of the waste from Seven-Eleven stores for appropriate processing and recycling.

Circular Economy in Agricultural Inititatives

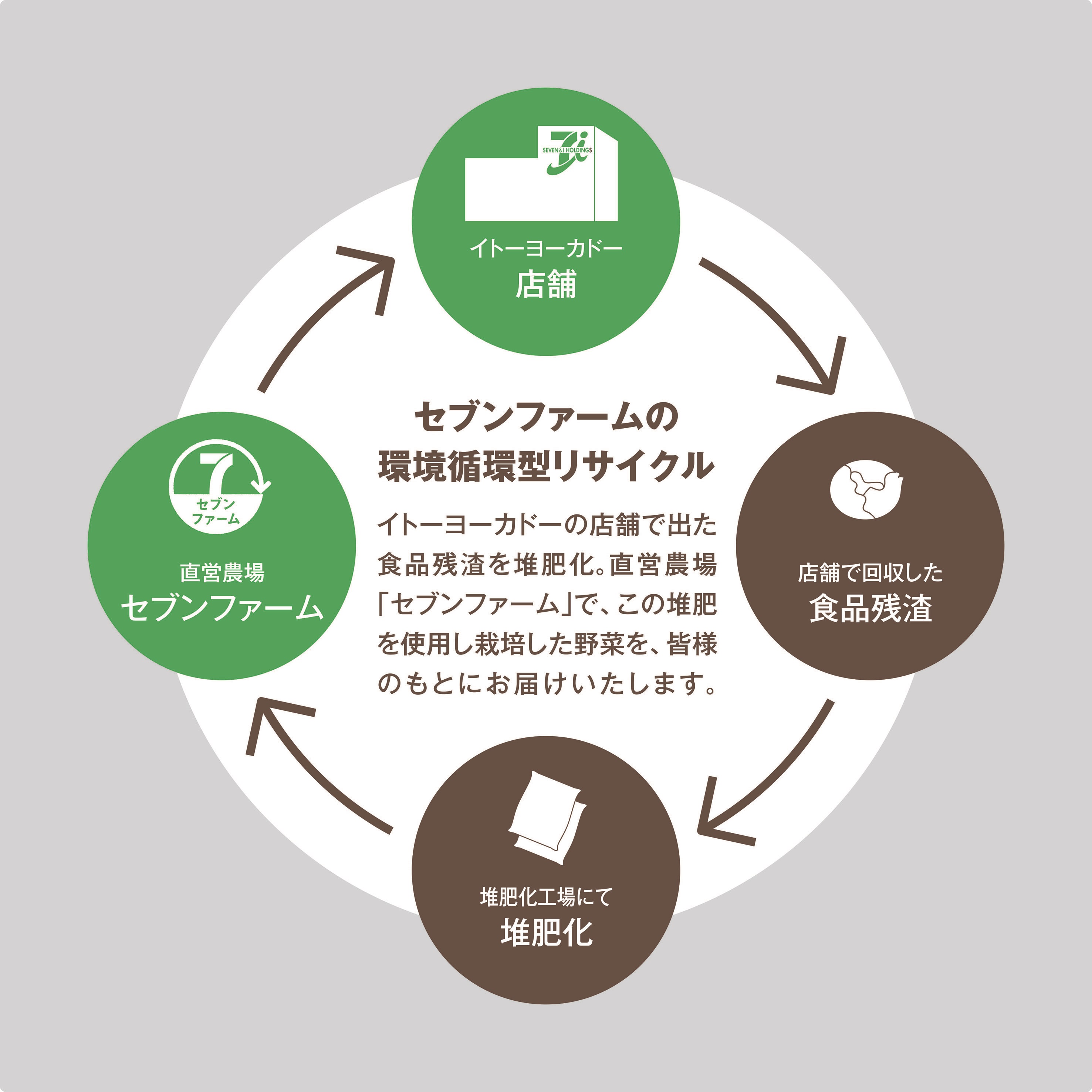

Establishment of Seven Farm

In August 2008, with the aim of enhancing recycling rates and revitalizing local agriculture, Ito-Yokado established “Seven Farm Tomisato” as an agricultural production corporation in Tomisato City, Chiba Prefecture, thereby becoming the first player in the retail sector to engage in “Circular economy in agriculture.” “Circular economy in agriculture” is an initiative for composting food residues (garbage) generated by Ito-Yokado stores and using it as fertilizer at Seven Farms. The produce that is grown at the farms is then harvested and sold at the stores from which the food residues were generated.

As of the end of March 2023, Seven Farm had expanded to 11 sites nationwide, Seven Farm is actively working to acquire certification under Japan Good Agricultural Practice (JGAP), an agricultural production process management technique, and all the 11 Seven Farm locations (as of the end of February 2024) have acquired JGAP certification.

Seven Farms

Seven Farms’ Circular Economy Model

Awareness-Raising Activities for Reducing Food Loss and Waste

In light of the fact that approximately half of food waste is generated by households, the Seven & i Group is conducting educational activities to reduce food waste at home. For example, some Seven & i Group stores conduct “food drives,” which involve customers bringing surplus food from their households to participating stores, with this food then donated to food banks. Food brought to the stores is distributed to people in need through food banks and social welfare organizations.

Ito-Yokado began installing permanent food drive collection boxes in its stores in June 2020. The foods collected at each store are centralized at distribution centers with the cooperation of contracted logistics companies, and then delivered to food canteens for children and persons in need of support through food banks. In addition, we implemented a food drive to raise employee awareness at venues including the Head Office of each Seven & i Group company and selected district offices of Seven-Eleven Japan.

Number of Stores with Food Drive Collection Boxes

| FY2021 | FY2022 | FY2023 |

|---|---|---|

|

44 |

75 |

83 |

Seven & i Food Systems is promoting initiatives to encourage finishing meals as part of its responsibility as a food service company. For example, at the end of February 2023, 38 local municipals nationwide have registered as stores that promote food waste reduction, such as stores that encourage customers to finish their meals. Additionally, since October 2019, Denny's menu has made it clear that there is a small-serving option for rice that is easy to finish, and it has displayed the “Loss Non” symbol used by the national movement to promote food loss and waste reduction.

Furthermore, the mottECO Project, an undertaking to reduce food loss implemented by Denny’s restaurants, was selected by the Ministry of the Environment as a model business for reduction of food waste over the four consecutive years from 2021. In the fiscal year ended February 29, 2024, the scope of this initiative has been expanded to become a seven-organization joint undertaking of public and private sector entities by also involving Royal Holdings Co., Ltd., SRS Holdings Co., Ltd., Nippon Hotel Co., Ltd., Keio Plaza Hotel Co., Ltd., Aleph Inc., and the municipal governing body of Suginami City, Tokyo. In this way, we are engaging in new activities of this kind which are of a nature unique to the food and beverages business. These activities are intended to facilitate the spread of a “culture of taking the initiative to bring home one’s leftovers,” by making available dedicated takeaway containers made using environmentally friendly materials, and thus allowing customers who wish to do so to bring home any unfinished food.

mottECO poster