- Top

- Sustainability

- Seven & i Holdings Material Issues

- Material Issues 3

- Introduction of Environmentally Friendly Packaging

- Sustainability

- Message from the Representative Director & Executive Chair (Kaicho)

- Basic Policies of Sustainability Initiatives

- Sustainability Management

- Stakeholder Engagement

- Business Partners

- Seven & i Holdings Material Issues

- Corporate Governance

- Compliance

- Information Security and Personal Information Protection

- Human Rights Initiatives

- Human Capital Initiatives

- Climate and Nature-related Information Disclosures —Responses to TCFD/TNFD Recommendations

- Social Contribution Activities

- Business Continuity Initiatives

- Overseas Initiatives

- Sustainability Data Book

- External Recognition and Awards

- SASB/GRI Index

- Index for Researchers

- Keyword search

- Editorial Policy

- Social

- Environment

Introduction of Environmentally Friendly Packaging

Product containers and packaging play important roles including preserving products and displaying information about ingredients, but after product use, these items become waste. In the “GREEN CHALLENGE 2050” Environmental Declaration, Seven & i Holdings Co., Ltd. and its consolidated subsidiaries (hereinafter referred to as "our Group") are promoting the reduction of the environmental impact associated with containers and packaging by pledging to make 50% of the containers and packaging used in original products (including Seven Premium) consist of environmentally conscious materials by 2030, and 100% by 2050.

Plastic Usage Reduction Initiatives

At York-Benimaru, we have devised sales methods for fresh food and delicatessen items that reduce the amount of containers and packaging used, such as selling by weight. In our delicatessen items sales areas, we are increasingly using paper bags rather than plastic containers for selling items such as croquettes and tempura. In some other stores, some products sold in fresh meat and fish sales areas have adopted the method of packing meat and fish for sale in plastic bags without a polystyrene tray.

At Seven-Eleven Japan, the lids on containers of the “Cup Deli” line of salad products have been changed to top-seal types, and the amount of plastic used per container has been reduced by about 30% compared to conventional containers.

Plastic Reduction* in Cup Deli: Seven-Eleven Japan

| FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

|

483 tons |

529 tons |

667 tons |

766 tons |

- *

- Comparison with the lids on conventional Cup Deli items

Example of packaging without trays (poultry)

“Cup Deli” products with top-seal lids

Denny’s Japan is collaborating with four hotel companies to reduce the amount of plastic used by installing SAWANNA automatic hand towel dispensers at 42 Denny’s restaurants. At Denny’s restaurants, paper hand towels are currently placed mainly at drink bars for customers to take freely. In addition to the need to reduce plastic usage, however, paper hand towels taken to tables in excess of the number of customers and being discarded unused is also an issue. The SAWANNA automatic hand towel dispenser is a system that dispenses wet paper towels when a customer holds their hand under the dispenser, and unlike conventional paper hand towels, no plastic packaging is needed. This initiative has led to a reduction of 60 kg of plastic usage per year in each store where the dispensers have been installed.

Shifting to Recyclable Packaging

In July 2015, we changed the paper cartons used for Seven Premium alcohol products from the previous aluminum carton material to a non-aluminum carton material. This change enables the cartons to be recycled as paper cartons. Moreover, the volume of CO2 emissions per carton from the raw material procurement and manufacturing process is around 12% lower compared with the aluminum cartons. Therefore, this initiative has resulted in a reduction in CO2 emissions of approximately 250 tons per year, the equivalent of the CO2 absorbed by approximately 18,000 cedar trees.

The identification mark also changed from the Paper Mark to the Paper Carton Mark

Use of Biomass Raw Materials

In the fiscal year ended February 29, 2016, Seven-Eleven Japan replaced the original Salad Cup Container sold in the chilled cases of its stores with containers that use environmentally friendly PET made from recycled or biomass PET rather than oil-based PET. Ito-Yokado also uses bioplastics that make partial use of plant-based oil materials for the containers in its cut fruit and boxed lunches.

Salad cup container made with eco-friendly PET

Cut fruit inside a bioplastic container

Adopting "Rice Ink" for Package Printing

In April 2016, Seven-Eleven Japan introduced rice ink for printing the packaging of rice balls sold at its stores. Rice ink is made from rice bran oil, a non-edible part of the plant extracted from rice bran. This ink reduces the Company’s annual CO2 emissions by around 60 tons compared with conventional petroleum-based inks and is therefore aiding in reducing environmental impact (botanical ink is used on some paper packaging). Moreover, the packaging is also contributing to our efforts to promote local production for local consumption by using domestically produced rice bran oil, which is one of the raw materials.

Product packaging made from plant-derived raw materials and rice ink prints

Introducing Paper Containers

Since June 2020, Seven-Eleven Japan has switched from conventional plastic to paper containers for “chilled boxed lunches.” In addition, by combining paper material for the parts of sandwich packaging that had used film material, we reduced our use of plastic by about 40%.

Plastic Reduction in Chilled Boxed Lunches

| FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

|

826 tons |

848 tons |

886 tons |

761 tons |

- *

- Comparison with conventional containers incorporating plastics

Paper container for chilled boxed lunches

Packaging that combines paper material within the red frames

Use of Forest Thinning Materials

Certain Seven Premium yoghurt drinks have containers made with Seven Forest thinning materials. Japan has a large number of unmaintained man-made forests that have been left unattended. With many such forests currently not fulfilling their potential as carbon sinks, use of forest thinning materials can contribute to the creation of healthy forests and prevention of global warming.

Introduction of Recycled Materials

Ito-Yokado is introducing recycled trays manufactured by suppliers that have received Eco Mark certification. In addition, some of the Group’s “Seven Premium” private brand products use recycled PET materials as part of the packaging film.

Reducing CO2 Emissions with the Use of Recycled Trays

| FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

|

Approx. 2,500 tons |

Approx. 2,500 tons |

Approx. 2,700 tons |

Approx. 3,000 tons |

再生トレイ

ペットボトルのリサイクル素材を採用したパッケージ

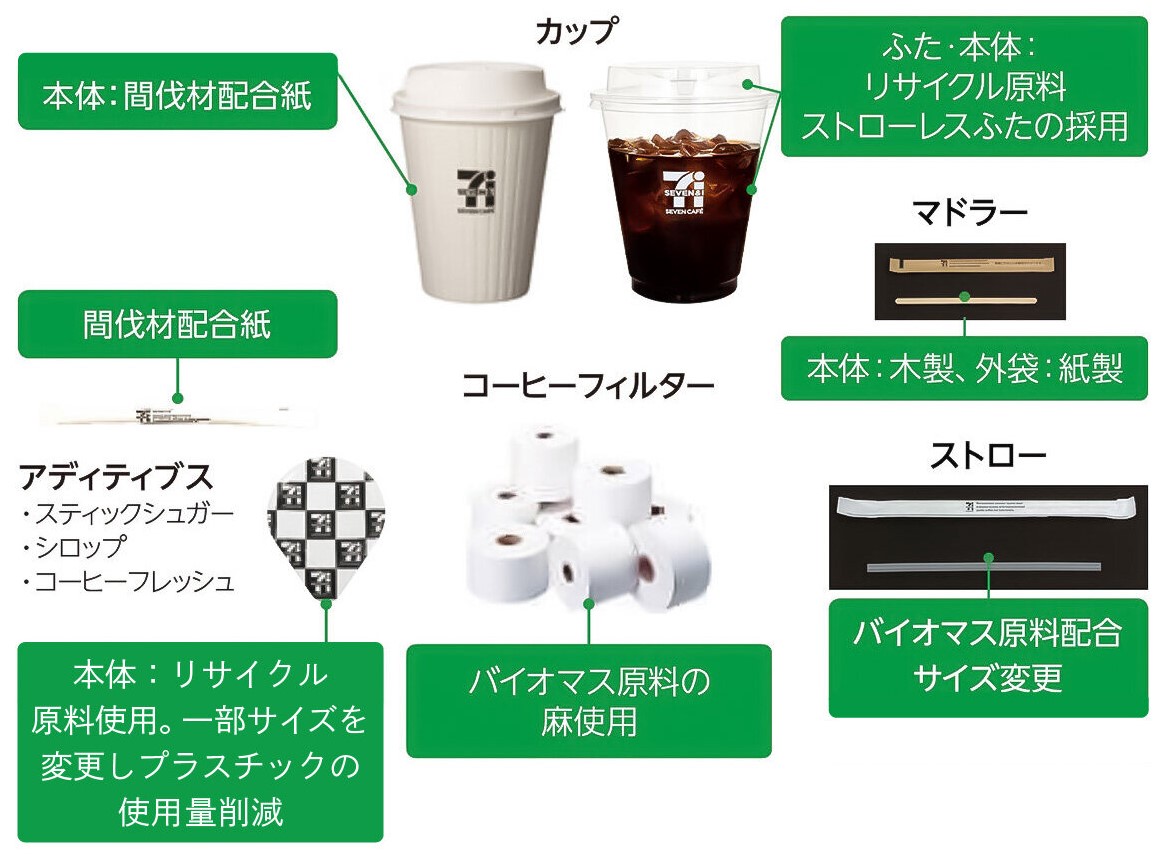

Environmental Efforts of SEVEN CAFÉ

Many customers support SEVEN CAFÉ, which is promoting environmental considerations in various ways. For example, forest thinning material is used for the outer sleeves for hot beverages. Cups for iced beverages use a compound material that includes recycled PET. We are also working to cut down our use of limited resources, for example by making cups lighter and thinner. We strive to make SEVEN CAFÉ environmentally-friendly.

In the fiscal year ended February 28, 2018, we also developed an antibacterial deodorizer that uses recycled coffee grounds collected from some of our stores. The new product is being used for cleaning at 7-Eleven stores.

Environmental Initiatives of SEVEN CAFÉ

Antibacterial deodorizer that uses recycled coffee grounds

Introduction of Environmentally Friendly Cutlery to All Stores Nationwide

To curtail the distribution of unneeded forks and spoons (cutlery) with the objective of reducing petroleum-derived plastic usage, for some time, 7-Eleven Japan stores have been asking customers whether they require cutlery with their purchases. In addition, we developed cutlery made from 30% plant-derived (biomass) materials, in conjunction with the coming into effect of the Plastic Resource Circulation Act in April 2022, and are deploying this environmentally-conscious cutlery nationwide.

Ito-Yokado is working to reduce petroleum-derived plastics with the use of plastic cutlery made with 25% biomass, including the runcible spoons and forks distributed at checkout counters.

Introducing Packaging for Underwear with Green Nano*

Our Group is changing the packaging for the underwear in the Group's "Seven Premium" private brand products to a green nano material in an effort to reduce CO2 emissions when they are incinerated.

- *

- "Green nano" is a technology developed in Japan to greatly reduce the amount of CO2 emitted during incineration just by adding a small amount of it to the raw materials for plastic

Usage Quantity of Packages Containing Green Nano

| FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

|

Approx. 5.0 million |

Approx. 4.8 million |

Approx. 4.5 million |

Approx. 4.2 million |

Usage of Environmentally Friendly Containers and Packaging Materials for Original Products

【Usage of Paper and Glass】

| Material | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Paper | 20,257t |

19,982t |

22,550t | 21,166t | |

| - Percentage of certified paper | 46.5% |

52.5% |

39.6% | 40.3% | |

| Glass | 6,441t |

6,108t |

5,178t |

4,442t |

|

| - Percentage of recycled glass |

69.0% |

73.4% | 75.4% | 78.5% | |

- *1

- Calculated from the annual report of the Japan Containers and Packaging Recycling Association

- *2

- Percentage of recycled glass is calculated from the annual report of the 3R Promotion Council for Glass Bottles

- *3

- Total of six companies: Seven-Eleven Japan, Ito-Yokado, York-Benimaru, Peace Deli, Akachan Honpo, and Denny's Japan

【Usage of Plastics made from eco-friendly materials】(Unit: t)

| Material type | FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|

|

Biomass |

901 |

1,016 |

1,172 | 1,153 |

| Biodegradable | 1 |

9 |

5 | 595 |

| Recycled | 11,110 |

17,363 |

25,429 | 26,933 |

| Total |

12,012 |

18,389 | 26,607 | 28,681 |

- *1

- Total of six companies: Seven-Eleven Japan, Ito-Yokado, York-Benimaru, Peace Deli, Akachan Honpo, and Denny's Japan

- *2

- Totals may not add up due to rounding of numbers