- Top

- Sustainability

- Seven & i Holdings Material Issues

- Material Issues 2

- Food Safety and Reliability

- Sustainability

- Message from the Representative Director & Executive Chair (Kaicho)

- Basic Policies of Sustainability Initiatives

- Sustainability Management

- Stakeholder Engagement

- Business Partners

- Seven & i Holdings Material Issues

- Corporate Governance

- Compliance

- Information Security and Personal Information Protection

- Human Rights Initiatives

- Human Capital Initiatives

- Climate and Nature-related Information Disclosures —Responses to TCFD/TNFD Recommendations

- Social Contribution Activities

- Business Continuity Initiatives

- Overseas Initiatives

- Sustainability Data Book

- External Recognition and Awards

- SASB/GRI Index

- Index for Researchers

- Keyword search

- Editorial Policy

- Social

- Environment

Food Safety and Reliability

Seven & i Holdings Co., Ltd. and its consolidated subsidiaries (hereinafter referred to as "our Group") are working on a variety of measures to emphasize safety and reliability at all stages from raw materials procurement through to sales.

Centralized Management of Production Records

Seven-Eleven Japan manages various daily food product items, which includes rice and delicatessen items. To accurately identify which factories produce them and what materials are used in which areas, Seven-Eleven Japan manages information from all its factories that make daily items by using a database system and links to the POS (point-of-sale) data at its stores to precisely manage the production history of its products, from the production region of the materials used to the stores where the products are sold. This allows us to immediately respond to any problems that may occur with raw materials. It also checks for the presence of allergic substances and additives in its products to ensure that they are sold with the utmost care.

In addition, Seven-Eleven Japan is also able to precisely track the volume of food materials, packaging, and containers used at every factory, which helps it reduce waste by limiting excess production, for instance. Moreover, the company voluntarily conducts DNA testing on rice to prevent the admixture of other varieties as well as testing for radioactive substances.

Seven-Eleven Japan’s Raw Material Production Record Management Framework

![Check history from raw ingredients: [Management data for raw ingredients] Data on the country of origin of each raw ingredient,manufacture and additives. Check production history from sales area: [Logistics management data] Data on raw ingredients, amount used, and usage period for each region Check production history from products: [Recipe master (menu recipe management data)] Data on raw ingredients used in products.](/library/dbps_data/_template_/_res/en/csr/201610/images/theme/theme2/traceability_2018_1.jpg)

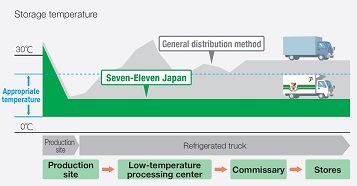

Introduction of Cold Chains

Various leafy vegetables are used in 7-Eleven’s original daily foods (rice balls, sandwiches, stuffed bread, salads, delicatessen items, noodles, and so on). We began introducing cold chains (low-temperature distribution networks) in 2005 for low temperature transportation and processing in order to maintain high levels of freshness of produce from harvesting in the field to delivery to stores. Harvested vegetables are consistently maintained at low temperature in delivery vehicles, at sorting centers and processing factories, and until placement on store shelves.

Cold chains (low-temperature logistics networks)

Providing Reliable Products

Products with Visible Production Areas

York-Benimaru has established a section called "The Secrets of Deliciousness, Safety, and Reliability" on its website, providing information on the production site, characteristics, production process, producers, and other aspects of the fresh food that the company has carefully selected.

Approach toward the Use of Food Additives

Seven-Eleven Japan aims for fresh, homemade taste for fresh foods such as boxed lunches, and when using food additives, uses the minimum amount and types necessary. Further, we have set voluntary standards for food additives and make every effort to minimize the use of food additives that are of deep concern to our customers. In addition, with regard to labeling on use of additives, we conform to the Consumer Affairs Agency’s “additive free and not-used guidelines” and promote labeling that does not mislead customers.

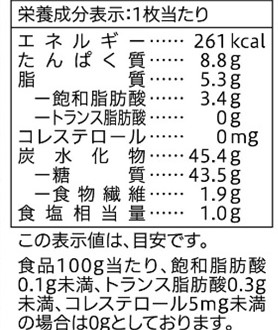

Reducing Trans-Fatty Acids

It is said that excessive trans-fatty acids increase bad cholesterol in the blood and reduce good cholesterol, heightening the risk of coronary heart disease among other things. In Japan, where intake is low compared to other countries such as Europe and the United States, there is currently no obligation to display trans-fatty acids and no upper limits have been set. However, we are voluntarily working to reduce the total amount of trans-fatty acids in product, including those under the Group's private brand "SEVEN PREMIUM."

Example of product with reduced trans fat: "SEVEN PREMIUM Gold" Golden Bread

Labeling of Food Allergy Information

Our Group, in addition to displaying information about eight specified ingredients (egg, milk, wheat, shrimp, crab, buckwheat, peanuts, and walnuts) that are required to be labeled under the Food Labeling Law, also recommends displaying information about 20 equivalent items※ so that people with food allergies can choose products with confidence.

- Items recommended for the “equivalent items” category: abalone, squid, salmon roe, oranges, cashew nuts, kiwifruit, beef, sesame, salmon, mackerel, soybean, chicken, banana, pork, matsutake mushrooms, peaches, yam, apples, gelatin, and almonds

Display on all Fresh Foods

Seven-Eleven Japan displays specified ingredients and equivalent items on all fresh foods, including boxed lunches, rice balls, sandwiches, delicatessen items, noodles, bread, and pastries. Additionally, for in-store cooked products (hot snacks, oden, Chinese steamed buns), the use of specified ingredients is displayed on in-store POP, and information on specified ingredients and equivalent items is disclosed on the website.

Display on Products Cooked In-store

At Ito-Yokado, in-store cooked sushi, delicatessen items, etc. are labeled with "specific raw materials" and "equivalent items (excluding almonds)." The food products in the container have allergy information on their labels. For the products sold separately without packaging, a list of allergens contained in each product is posted at the store.

Display on menu book and terminal tablet

Denny's Japan provides allergy information on their website in a tabular format, and customers can also search the menu name by allergen only in Denny's in-store menu.

Sales of Products with Food Allergy Considerations

Our Group offers a low-allergen menu to make meals delicious and enjoyable, regardless of food allergies or not.

Sales of "Low-Allergen Menu and Low-Allergen Cake”

At the Denny’s restaurant chain managed by Denny's Japan, there is a low-allergen menu and low-allergen cake for children that do not include any of the eight specified allergens (eggs, milk, wheat, buckwheat, peanuts, shrimp, crab, and walnuts), created out of consideration for children who have food allergies. When the meals are prepared at the restaurants, employees cook and arrange the food in an area separate from the regular cooking line, and the tableware is individually washed and stored to prevent secondary contamination by allergens.

Low-allergen menu

Low-allergen cake

Conducting Food Allergy Workshops

Seven-Eleven Japan has been hosting workshops for people with food allergies and their guardians since 2021 in collaboration with a certified non-profit organization. At the workshops, actual food selection experiences are shared with participants, and feedback from participants is used to improve product labeling with the aim of making products more user-friendly.

Workshop on food allergies 1

Workshop on food allergies 2

Regarding Handling of Genetically Modified Foodstuff

Our Goup labels genetically modified foodstuffs in accordance with relevant domestic regulations. In addition, genetically modified ingredients are not used for the main ingredients—for which labeling is obligatory—of products under the Group’s private brand Seven Premium (excluding certain products such as soy sauce and oil which use genetically modified potatoes, corn, soy beans, and other products which are permitted to be imported by the Japanese government).

Inspection for Radioactive Substances

In response to an increase in inquiries about radioactive materials since the Great East Japan Earthquake, our Group voluntarily conducts inspections to complement the monitoring conducted by the government, and we have posted details on our website. Inspections for radioactive substances are conducted for Ito-Yokado’s Traceable Foods with Producers' Faces and the results are published on its website.