- Top

- Sustainability

- Seven & i Holdings Material Issues

- Material Issues 2

- Building Quality Control Systems

- Sustainability

- Message from the Representative Director & Executive Chair (Kaicho)

- Basic Policies of Sustainability Initiatives

- Sustainability Management

- Stakeholder Engagement

- Business Partners

- Seven & i Holdings Material Issues

- Corporate Governance

- Compliance

- Information Security and Personal Information Protection

- Human Rights Initiatives

- Human Capital Initiatives

- Climate and Nature-related Information Disclosures —Responses to TCFD/TNFD Recommendations

- Social Contribution Activities

- Business Continuity Initiatives

- Overseas Initiatives

- Sustainability Data Book

- External Recognition and Awards

- SASB/GRI Index

- Index for Researchers

- Keyword search

- Editorial Policy

- Social

- Environment

Building Quality Control Systems

Seven & i Holdings is working to introduce international management system standards and management methods regarding quality and hygiene in order to provide safe and reliable products to customers.

Establishing a Foundation for Quality Control in Each Group Company

Seven & i Holdings Co., Ltd. and its consolidated subsidiaries (hereinafter referred to as "our Group") handle products whose safety has been ensured through checks by the quality control department before purchasing them. Seven & i Holdings is working to establish quality control systems, recognizing that a product incident at one Group company affects the entire Group. Quality control managers at the development division for the Seven Premium line of Group private brand products, 10 Group companies that handle food products, and 6 that handle apparel and household items meet regularly to share their policies and information. These activities are designed to prevent incidents and strengthen the Group’s ability to respond rapidly when incidents occur. Specifically, Group companies have established the following foundation for quality control.

Establishing a Foundation for Quality Control

- A system in which specialized quality control departments can objectively determine responses to incidents

- A system for reporting a serious incident quickly to the Representative Director and President

- Guidelines for judging whether to recall products or continue sales if a serious incident occurs

Quality Control Training for Employees

Our Group conducts regular employee training on quality control for product development and procurement staff, as well as sales floor staff, to prevent product accidents. In the fiscal year ended February 28, 2025, with the goal of nurturing future leaders in quality control, we are developing an educational curriculum utilizing external organizations and instructors. This curriculum aims to provide basic knowledge training and a wide range of quality control skills.

Results of training held by Seven & i Holdings in the fiscal year ended February 28, 2025

| Training details | Participants | Target |

|---|---|---|

| HACCP 3-day training | 18 | Those handling procurement of product, those in charge of quality control |

| Supplier auditor training | 14 | Those handling procurement of product, those in charge of quality control |

| ISO 9001 internal auditor 2-day training | 11 | Those handling procurement of product, those in charge of quality control |

| Beginner level Food poisoning (1) | 77 | Those handling procurement of product, those in charge of quality control |

| Beginner level Food poisoning (2) | 75 | Those handling procurement of product, those in charge of quality control |

| Food labeling (1) | 47 | Those handling procurement of product, those in charge of quality control |

| Food labeling (2) | 41 | Those handling procurement of product, those in charge of quality control |

| Food labeling (3) | 38 | Those handling procurement of product, those in charge of quality control |

| Food labeling (4) | 38 | Those handling procurement of product, those in charge of quality control |

| Beginner level Allergies | 58 | Those handling procurement of product, those in charge of quality control |

| Food incidents | 88 | Those handling procurement of product, those in charge of quality control |

| Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices | 118 | Those handling procurement of product, those in charge of quality control |

|

(1) Household Goods Quality Labeling Act (2) Japanese Industrial Standards |

101 | Those handling procurement of apparel and household goods, those in charge of quality control |

|

(1) Basic knowledge of kitchenware (2) Basic knowledge of fashion accessories |

76 | Those handling procurement of household goods, those in charge of quality control |

|

Investigating the causes of daily necessities issues |

52 | Those handling procurement of household goods, those in charge of quality control |

|

Analysis of complaint causes |

60 | Those handling procurement of household goods, those in charge of quality control |

|

OEKO-TEX certification seminar |

26 | Those handling procurement of apparel and household goods, those in charge of quality control |

Acquiring Quality Management Certification

Our Group has implemented a system requiring business partners to acquire various certifications to strengthen quality control for products such as foodstuffs, clothing, and household goods.

Participation in the Japan Food Safety Management Association

Seven & i Holdings became one of the founders of the Japan Food Safety Management Association (JFSM)*1, established in 2016 as the primary Japan-created operating body for food product safety management standards, along with food product manufacturers both in Japan and overseas. We did this in partnership with food-related companies, the Ministry of Agriculture, Forestry and Fisheries, and university researchers with the goal of responding to the increased handling of imported foods (globalization) in Japan and improving domestic food safety management. By utilizing the JFS standard*2 developed by this association, we aim to improve food quality as a retail group that is building a supply chain.

Currently, five Group companies*3 that handle food products have become JFSM members and are promoting the improvement of food safety management levels within the Group. In addition, we are proceeding with the acquisition of JFS standard certification and conformance certification for factories that manufacture the Group's “Seven Premium” private brand products and fresh foods such as Seven-Eleven’s boxed lunches, rice balls, sandwiches, delicatessen items, noodles, and bread.

*1 An organization that creates and operates a Japanese food safety management standard (the JFS standard) and its certification/conformance certification system.

*2 A Japanese food safety management standard developed by JFSM that conforms to international standards that include Codex HACCP.

*3 Seven-Eleven Japan, Ito-Yokado, York Benimaru, SHELL GARDEN, Denny's Japan

Obtaining Certification of Food Safety Management Standards that Conform to International Standards

Fresh Food, our original products such as boxed lunches and delicatessen items sold at Seven-Eleven stores, are made by daily manufacturers who are members of Nihon Delica Foods Association (NDF)*1. In October 2018, NDF revised the NDF-HACCP Certification System to the NDF-FSMS certification system*2 in response to the institutionalization of HACCP for the international standardization of food sanitation management. In addition, in March 2020, all NDF member daily manufacturers obtained certification and conformance certification. (Number of the factories as of the end of February 2025: 173)

Similarly, we are working on obtaining certification and conformance certification related to food safety management standards that conform to international standards that include Codex HACCP, such as ISO 22000, FSSC 22000, and the JFS standard, at all manufacturing factories that produce the Group's “Seven Premium” private brand products. (As of the end of March 2025, 100% of the manufacturing factories have obtained certification.)

*1 NDF was formed in 1979 to improve hygiene quality management levels at Fresh Food manufacturing facilities and to eliminate region-based quality differences.

*2 FSMS: The Food Safety Management System (FSMS) is a system designed to manage potential food safety hazards in order to ensure delivery of safe and reliable foods to consumers.

Acquisition of GAP Certification

Ito-Yokado is recommending the acquisition of Good Agricultural Practice (GAP) certification, an agricultural production process management method, in order to further improve the level of our quality management of its private brand “Traceable Vegetables with Producer's Faces” and “Traceable Fruits with Producer's Faces." GAP certification sets standards that should be implemented in day-to-day farm management to improve safety and protect the environment. Certification has been acquired by 307 producers as of the end of February 2023, and efforts will be made for further certification going forward.

Number of GAP Certification Holders

| End of February 2022 | End of February 2023 | End of February 2024 | End of February 2025 |

|---|---|---|---|

|

226 |

307 |

360 |

348 |

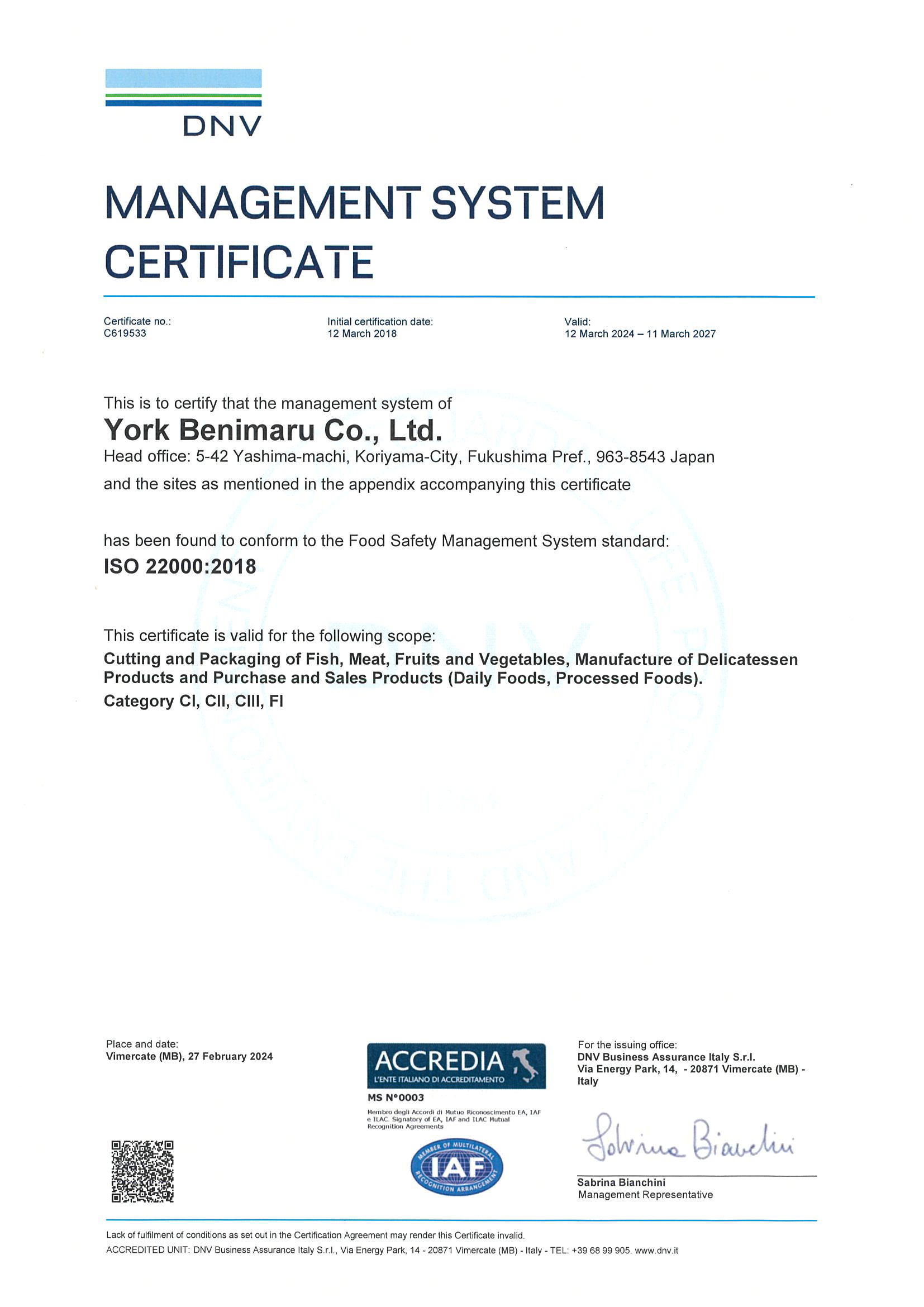

Acquisition of ISO 22000 Certification

York-Benimaru Co., Ltd. acquired certification under ISO 22000, an international food safety management system, at its Otsuki Store in Koriyama City, Fukushima Prefecture in March 2018. The scope of certification was subsequently expanded to include York-Benimaru Headquarters, which also acquired certification. Going forward, York-Benimaru will utilize the experience gained from acquiring ISO 22000 certification to implement HACCP systems at all stores while providing employee training at each store. York-Benimaru will also strive to further improve the quality of our products, from product procurement to sales, in order to ensure even greater safety and reliability on the dining tables of our local customers.

Peace Deli (Kazo Kitchen), a Group food manufacturer, acquired ISO 22000 certification in August 2016.

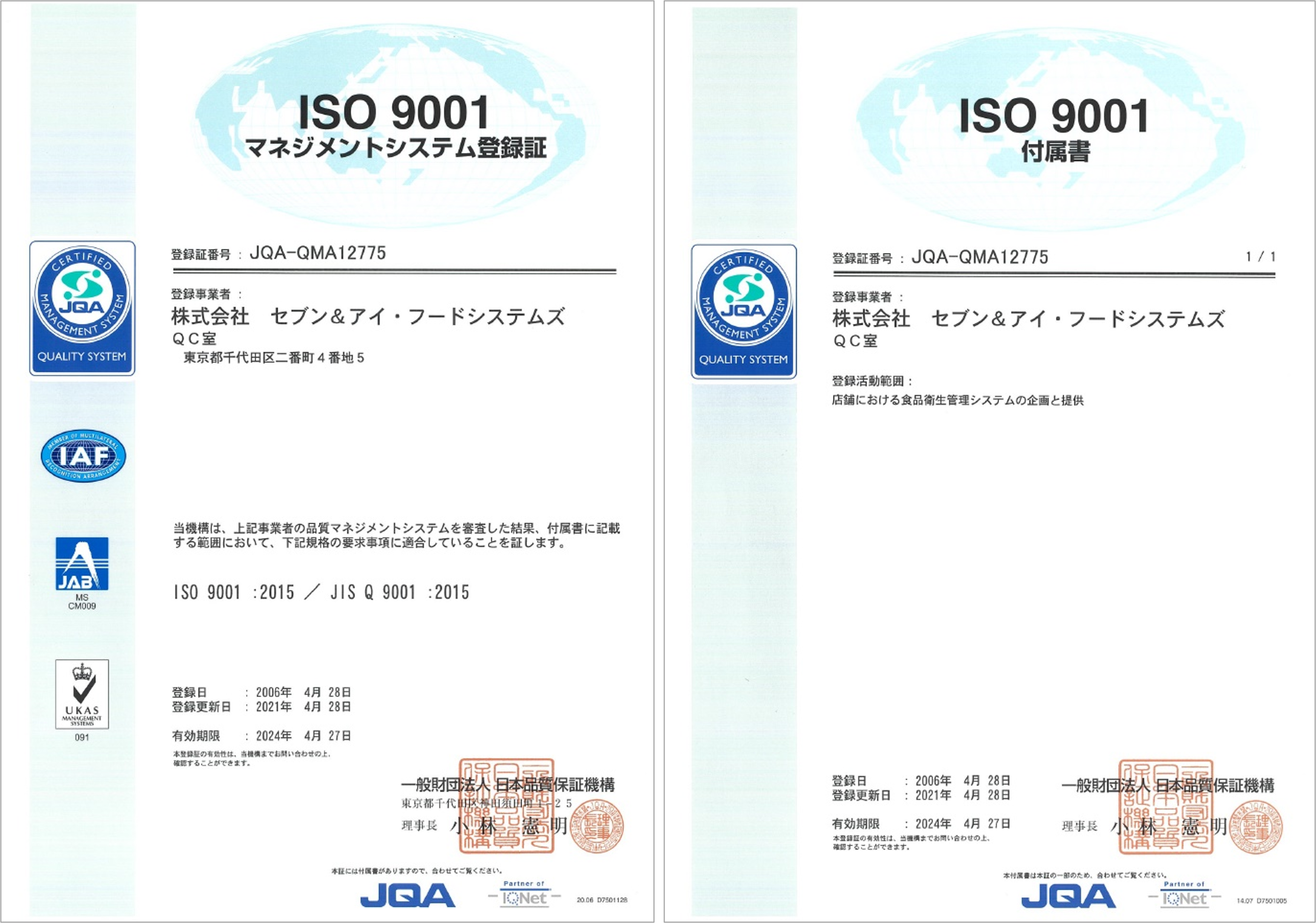

Hygiene Management Based on ISO 9001

Denny's Japan's QC Office, the hygiene management department, has acquired the ISO 9001 international standard concerning quality management. Utilizing this system, the company is working to boost both hygiene management and employee training (application scope: Planning and Provision of Food Hygiene Management Systems in Stores).

In hygiene management, priority is placed on freshness management that is easy to understand and can be performed by anyone. The QC Office and others conduct checks at stores, and random checks of store hygiene are also conducted by a third-party hygiene inspection organization (wipe inspections). Store employees undergo periodic hygiene management training to raise hygiene management levels.

Audits of Processes at Apparel and Household Goods Manufacturing Factories

Our Group sells apparel and household items, such as the Group's “Seven Premium” private brand products, while Group companies sell their own private brand products as well. To ensure the safety of these products, we conduct audits of our processes at our manufacturing factories both in Japan and overseas.

Since there is no official certification for manufacturing factories that guarantees a level of quality control for apparel and household items, Seven & i Holdings has established its own standards, and each Group company carries out external audits through specialized external institutions based on these standards. Seven & i Holdings issues a process audit “Compliance Certificate” to factories whose audit results have cleared certain standards.

Compliance certificate

External Recognition for Initiatives Addressing Quality Control

Ito-Yokado received the METI Minister Award at the Minister of Economy, Trade and Industry Product Safety Awards*1 three times, and was also certified as a gold product safety company*2 in the fiscal year ended in February 29, 2016—a first for a general supermarket. In March 2021, Ito-Yokado was again certified as the gold product safety company upon undergoing a follow-up audit, earning the single star Gold PS Award mark.

*1 The Ministry of Economy, Trade and Industry has been conferring this award since fiscal 2007 to raise awareness of corporate product safety and establish a culture of product safety that spreads the important value of product safety beyond the boundaries of companies to create a society where product safety is protected everywhere.

*2 Every five years after certification, the review committee will follow up to see if the efforts being made at the time of certification are still being maintained.

- Ito-Yokado received the METI Minister Award at the Minister of Economy, Trade and Industry Product Safety Awards in 2011, 2013, and 2015.

- Ito-Yokado was certified as a gold product safety company in 2015.

- Ito-Yokado was certified again (follow-up) as a gold product safety company in 2020.

- Ito-Yokado was once again certified as a gold product safety company in 2021.

single star Gold PS Award mark